Boiler Room

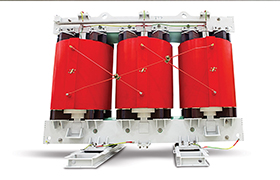

From 100 kVA to 10 mVA, three-phase, single-phase, AN / AF-cooled up to 52 kV isolation level, high-quality performance Cast Resin Dry Type Distribution Transformers for different applications are available. Thanks to its special and international standards, transformers are used at high altitudes and in marine environments, especially in severe conditions. Lack of flammable liquid, self-extinguishing material, free from toxic gas emissions, low noise level and low electromagnetic emission ensure overall environmental safety. Cast Resin Dry Type Distribution Transformers are suitable for operation in humidity-proof, humidity or severe pollution environment. These transformers can operate at low temperatures up to -25 ° C and are ideal transformers for more than 95% humid environments.

They are manufactured in a range of 10-100,000 kVA, with a single-phase, oil, cooled, on-load tap-changer or under-load tap-changer, up to 66 kV high voltage, both externally and internally. The dimensions of the expansion tanks of the transformers are designed as a result of the calculations to store the expansion of the oil with increasing temperature. Since the transformers with the expansion tank are open to the atmosphere, the oil pressure is changed due to the thermal effects and the air is exchanged by taking the moisture of the air through the silica gel (air dryer) in the tank of the transformer.

They are manufactured in a range of 10-100.000 kVA, up to 66 kV high voltage, with three or single phase, oil, refrigerated, on-load tap-changer or under load with automatic tap-changer, both externally and internally. The dimensions of the expansion tanks of the transformers are designed as a result of the calculations to store the expansion of the oil with increasing temperature. Since the transformers with the expansion tank are open to the atmosphere, the oil pressure is changed due to the thermal effects and the air is exchanged by taking the moisture of the air through the silica gel (air dryer) in the tank of the transformer.

They are manufactured in a range of 10-3.150 kVA, up to 36 kV high voltage level, with three or single phase, oil, cooling, idle on-load tap changer or automatic tap changer under load, both externally and internally. In hermetic transformers, there is no oxygen in the environment because the oil does not come into contact with air. There is therefore no aging due to oxidation. Hermetic Transformers will not get moisture from the transformer oil since there is no contact with air. In this way, Hermetic Transformers have a longer service life than transformers with expansion tank. Since hermetic transformers do not have an expansion tank, the height is low. Allows installation in smaller areas. Particularly advantageous in compact transformer centers.

In pipes, on surface or under plaster, in connection with distribution facilities, in damp places, in outdoor facilities, in portable devices (in heaters), in places where mechanical stresses are not present, in power stations, in public facilities as internal construction cables, in industrial facilities in cable ducts, in pipes and pipes It is used in the presence of rodent animals, in signal circuits and in water, in energy distribution networks, in urban lighting, in industrial plants or in unexpected distribution centers of mechanical damage. It is also resistant to oil and various chemicals. All relevant features are separated by product codes.

It is used in electrical supply of residential and industrial areas where short circuit currents are large, outside, in cable ducts, indoors and under ground, where there are mechanical stresses, under ground. All relevant features are distinguished by product codes.

It is used in electrical power supply, outside, cable ducts, indoors and under ground in residential and industrial areas where the short-circuit currents are large and in the conduits where the short-circuit currents are large. All relevant features are distinguished by product codes.

It can be used in indoor and outdoor places where there are many people, such as dry places, distribution systems, lighting in enterprises, schools, hospitals, meetings and shopping centers. All relevant features are separated by product codes.

These cables are used in dry and humid places. It is resistant to ozone, oil and various chemicals.

Upon request, all kinds of special panels can be produced in special types and sizes according to the needs of the project, according to the place of use and customer request. Computer-designed precision cutting-drilling operations on the punch table of the panels: twisting operations on press brakes, cutting-drilling-bending operations on eccentric presses, joining operations with gas welding, production in accordance with the project and in international norms. All kinds of compensation panels are manufactured according to the requests of our customers. All of our panels are TSE ISO 9001-2008 and CE certified.